|

(A) Railway Signalling IL made a modest start in the Railway Signalling field in the year 1985 by successfully executing a turnkey job for two wayside stations in Kota Division of Western Railway. The job involved design, engineering, manufacturing, and supply of material for the provision of Panel interlocking system at these stations. PI system provides for the failsafe operation of Signals and point machines for the movement of trains. The “Domino type” control-cum-indication panel, Relay racks, Cable termination racks, Power supply panels etc required for the system were manufactured for the first time. Enthused by this initial success, IL ventured into the Railway Signalling field in a major way. Now Railway Signaling Systems is one of the major areas of operation for IL. IL has achieved a high degree of

excellence in designing, manufacturing, supplying, installation, testing and

commissioning of Railway Signaling Systems comprising of Panel Interlocking,

Route Relay Interlocking, Multi Aspect Colour light Signaling etc. The complex

circuit designs for the systems are carried out on computer aided systems

Many such jobs have already been executed for Western Railway, Central

Railway, Southern Railway, Central Railway, Railway Electrification, RITES,

IRCON, NTPC etc. The turnkey jobs involve design, engineering, manufacturing,

supply, installation, testing and commissioning works. The engineers are well

trained and experienced to carry out the design of Railway Signalling systems

using proven as well as non-proven type of relays. The types of relays

manufactured are Ordinary DC neutral line relays, Track relays, both AC immune and Non-AC Immune. These relays

are supplied duly inspected by Railway Design and Standards Organization of

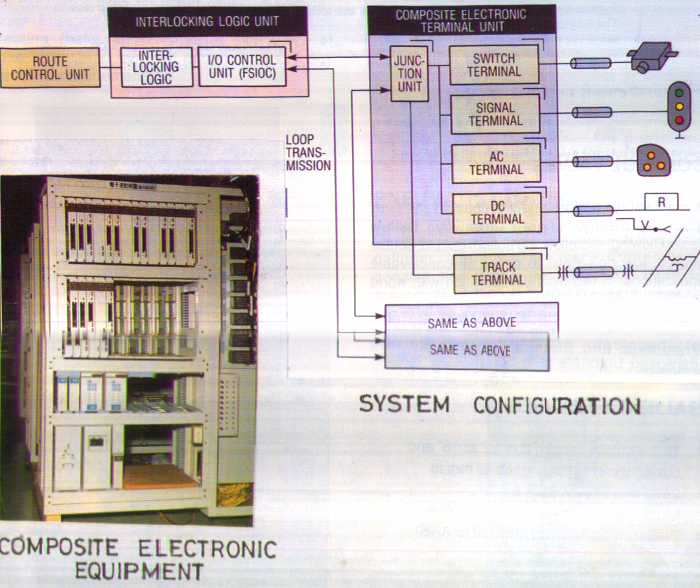

Indian Railways (RDSO). The unit is ISO-9001-2008 certified. Apart from the conventional relay based systems, IL have supplied K-5B/K5BMC type Solid State Interlocking (SSI) system to Indian Railways as well as steel plant in collaboration with M/s Kyosan Electric Manufacturing Co Ltd., Japan. M/s Kyosan have supplied and executed more than 400 system in Japan and overseas countries and enjoys about 70% of Japanese market. The SSI systems supplied are working satisfactorily in the high-density routes and have excellent track record of safety. The

SSI system of M/s Kyosan, Japan (Model K5B/K5BMC) employs 2 out of 2 computer architecture having same hardware and same software for the Main interlocking Logic

Unit, Electronic terminals for relay interface, Signal Control, Switch Control

etc. The panel interface electronic

terminal units and system monitoring units are configured in single computer

configuration. In the normal system called Duplex system, all these units i.e.

Main interlocking logic unit and Electronic terminal units are further

duplicated to be used as hot standby. However,

there is a flexibility to configure the system in Single configuration or we may

employ the main interlocking logic unit in hot standby.

|

||

|

(B) Manufacture of Goods Wagon (Both MS & SS ) Body Arrangements including side walls, End walls, Flap doors & Body side hold etc. IL entered in the field of refurbishment of goods wagons for Indian Railways in year 2009. IL have already supplied Body side arrangements i.e.set of left & right side walls , Flap doors against the orders secured from west central railways, Jabalpur and Kota for BOXN wagons i.e. MS coaches. These items are being supplied duly inspected by RITES. The quality of the product has been found highly satisfactory. The efforts are on to commence refurbishment of SS wagons, also for which infrastructure / facilities are being enhanced as per RDSO requirement. (C)

Manufacture of Control panels / Switch Board cabinets for LHB Coaches: IL have commenced Manufacture & supply of Control panels / Switch Board cabinets for LHB types of coaches manufactured by Railway Coach factory, Kapurthala. Some of these panels/ cabinets have already been made part of LHB coaches manufactured by RCF and found to be working satisfactorily. IL is in advanced stage of obtaining RDSO approval for these items , consequent to transfer of design document by RCF to RDSO and procurement made mandatory by RDSO approved vendors. |