Control &

Instrumentation

This

is the main area in which IL operates. The company was set up to meet the

Control & Instrumentation requirement of Process industries of India.

The company dedicates itself to this task with full sincerity to ensure

rapid economic development of the country based on timely commissioning of

various projects and satisfactory operation/ maintenance of already commissioned

projects at a high level of efficiency, availability and plant utilization

factor as far as the Control & Instrumentation is concerned.

IL’s

Process control market can be segmented in to Industrial categories such as

Power generation, especially Thermal Power Plants, Mining & Metallurgy

including Iron & Steel production, Non-Ferrous metals like Aluminum and

Copper / Zinc Smelter & Refineries, Petrochemicals including Oil & Gas

Production, Chemicals including Pharmaceuticals & Water treatment plant,

Cement, Paper, Fertilizers etc.

IL

has been a saga of success through hard work, vibrant ethos and high level of

team spirit. A strong turn-key capability has been established through expertise

in System design, Engineering, software development, Manufacturing, Testing,

Installation, Commissioning and after sales service.

IL can take pride of having supplied Control & Instrumentation Systems on turn-key basis to over 200 Thermal Power stations in Power sector( almost all Electricity Boards & NTPC plants), almost all Steel sector projects ( Bokaro, Bhilai, Rourkela, Durgapur of SAIL, Nilanchal Ispat, Vizag Steel plants, Jindal steel and other private steel plants etc.), and state of the art Digital Control system and other products to Refineries, Oil & Gas, Petrochemicals and Chemical plants ( IOCL Barauni, Guwahati, Mathura, Haldia, Panipat, NRL, BRPL, MRL, HPCL,BPCL, IPCL Vadodara / Nagothane, ONGC Mumbai, GAIL etc.), IL has also entered in to areas like Oil well Instrumentation, Marine Instrumentation etc. to supplement Companies growth.

Thermal

Power Plants: IL

is the only Indian company which has the privilege of supplying & executing C&I jobs on turn-key

basis for thermal power units ranging from 30 MW to 500 MW through out the

country and overseas. IL has also successfully executed the speedy

‘Restoration’ of

the several units which were damaged due to some unfortunate incidents.

Thus IL has proven capability of executing not only new Power Projects but also in upgrading of the old C&I

system with the State-of-the-art technology. For

the large projects IL has supplied DDC System of world-renowned manufacturers like

ABB, Seimens, HF Controls,

Emerson

and Max

Controls.

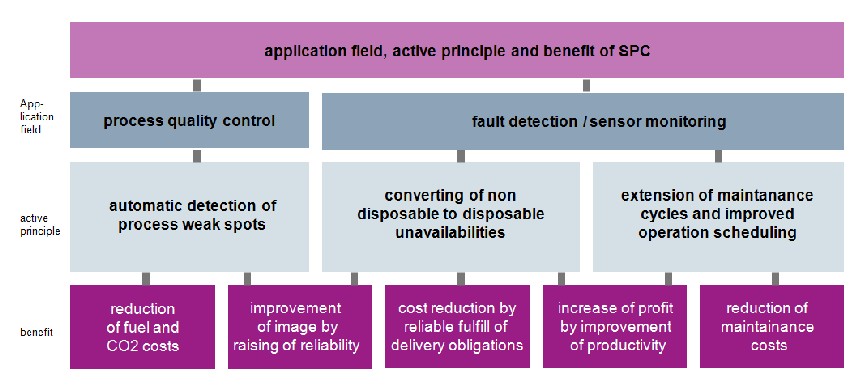

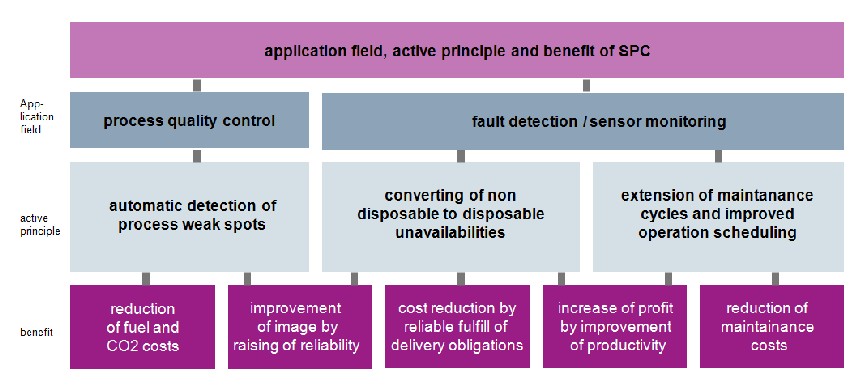

PADO

|

Instrumentation Limited (IL) has

successfully diversified in the field of Latest software based packages for

optimization of power plant for which PADO (Performance Analysis, Diagnostics

& Optimization software) has been implemented in RRVUNL, 250 MW Unit No.

#1 of Chabra Thermal Power project. Similar packages are already implemented

in other units of RRVUINL.

PADO the Performance Analysis,

Diagnostics & Optimization software is an online decision support system

which is time tested and has been very widely deployed to maximize the energy

efficiency during power generation. It has several modules each one of which

contributes positively and in its own way in improving efficiency.

|

|

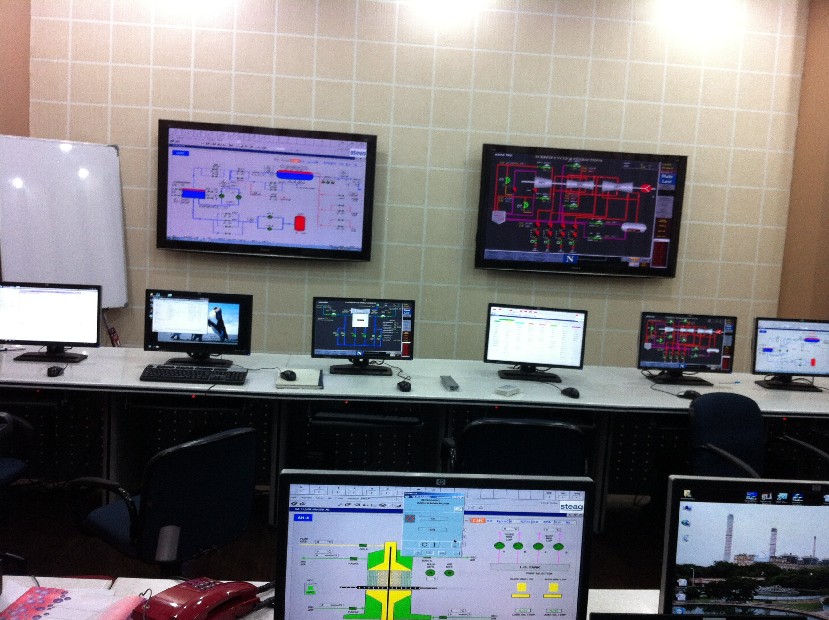

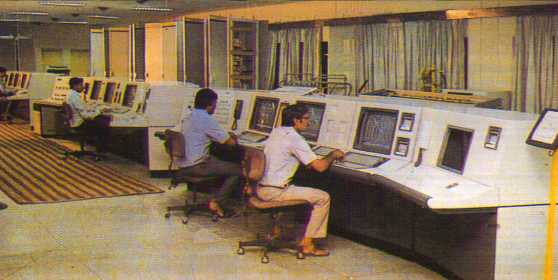

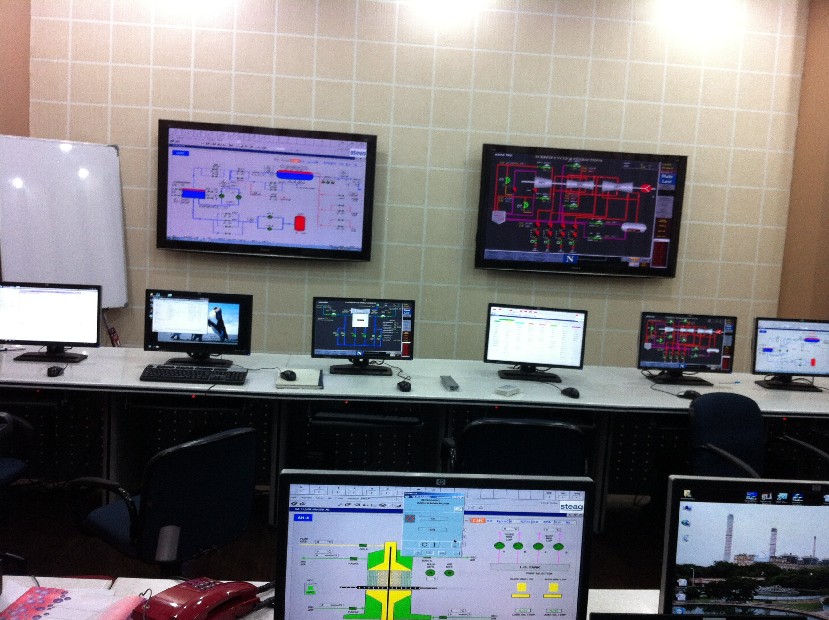

TRAINING SIMULATOR

|

Instrumentation

Limited (IL) has also achieved mile stone in providing Training to Power Plant

Operation plant for safe & efficient operation of Power Plants, for which

Operator Training Simulator Systems are successfully installed at RRVUNL Kota

& Suratgarh Thermal Power Stations.

As

per the study conducted by EPRI, USA benefits of Simulator training in terms

of availability, thermal performance, component life and environment

compliance savings, average Rs. 2.00 lakhs per MW per year. In the Indian

context, for nearly 70,000 MW of Thermal Power, the annual savings would be

Rs. 1400 Crores, presuming that the operational efficiencies of thermal Power

Plants are as good as that in US.

The major functions are:

-

Train and enhance Operator Skills for New Plants, Retrofit of New Control Systems ,Assignments in New Units

-

Training on same type of Operator interfaces is provided as in the real plant.

-

Any type of emergency condition can be created to train Operators in emergency handling

-

Training schools and training departments in different power utilities

|

Training Simulator

|

AMC Work

IL is doing Annual Maintenance contract of C&I system/ equipments in various Thermal Power Projects for last 10 years in UPRVUNL, RRVUNL etc. The work includes round the clock maintenance of various DCS system like MAX-DNA system, SMAR DCS system along with primary & secondary C&I equipments connected with the DCS system. For carry out above work IL engaged qualified Engineer/ Supervisors, Technicians/ Electricians in general as well as shift duty , IL maintains all the required parameters round the clock along woth Auto control of various loops like Drum level, Hotwell level, dearator level, SH/RH Temperature Control, Cold/Hot PA header pressure etc. so as to achieve maximum PLFof the machinepresently , we are doing following round the clock AMC of C&I system in various power projects of UPRVUNL. The details are as under:

1. AMC of Unit# 4&5, 2x500 MW, BTPS , Anpara TPS for last 15 years

2. AMC of Unit# 6&7, 2x110 MW, ATPS , OBRA TPS for last 12 years

3. AMC of Unit# 1&2, 2x50 MW, ATPS , OBRA TPS for last 1 years

4. AMC of Unit# 1&2, 2x110 MW, ATPS & Unit# 3&4, 2x250 MW, BTPS, Paricha TPS for last 6 years

5. AMC of Unit# 5 , 55 MW & Unit # 7, 110 MW of

Harduaganj TPS .

Since Last ten years , we are carrying out the Annual Maintenance Contract of Unit # 1&2 at Giral Lignit Power Limited, Barmer . The Total contract value is 200 Lacs Approximately.

Under this contract we are carrying out the following Jobs:

1. Around the clock running maintenance of C&I system of Boiler, TG, Water treatment plant and Light processing.

2. Break down maintenance

3. Annual overhauling.

Round the clock operation of Thermal power Plant Units:

Recently IL has been awarded the work of Round the Clock operation ( in 4 relay shift) of Unit # 1&2, 2x50 MW ATPS, UPRVUNL, Obra. To carry out the above work IL have engaged trained operator at various locations for smooth operation of the units which includes Auxiliaries of Boiler/ Turbine area, experienced engineer on desk for operation which includes Boiler light up to synchrinisation of machine with the grid . Customers have shown faith on IL and have awarded the work and IL had successfully doing the operation of above units and the PLFof both the machine is more than 95%. Based on the performance of IL, recently RVUNL have also awarded the work of operation of Unit# 1 , 250 MW , Chabra TPS and Unit #7 of 195 MW , Kota STPS . To carry out the above work IL has engaged around 200 Nos. trained manpower for this work.

We have providing operation assistance to following power plants:-

1. 2x50 MW Unit # 1&2 , Obra Thermal Power station, Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited.

The contract order value is Rs. 234 Lacs.

2. 55 MW Unit # 5 , Harduaganj Thermal Power station, Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited.

3. 1x195 MW Unit # 7 , Kota Super Thermal Power station, Rajasthan Rajya Vidyut Utpadan Nigam Limited.

The contract order value is Rs. 173.13 Lacs

4. 1x250 MW Unit #1 , Chabra Super Thermal Power station, Rajasthan Rajya Vidyut Utpadan Nigam Limited.

The contract order value is Rs. 464.04 Lacs

Under this contract we provide

Shift incharges, Control desk Engineer & Field operators around the clock in the shifts.

Being a

specialized nature of job, IL accepted the challenge and is doing the operation

of these Units successfully and customer is fully satisfied with the performance

of IL and is planning to give operation of other Units also.

Steel

Plants:

IL

is the only Indian company to have

the privilege of supplying &

executing the C&I jobs on turn-key basis in almost all the steel plants. IL

has done automation job for various mills like Blast Furnace, Coke-Oven Battery,

Slab/Strip/Rolling Mills, Wheel & Axle Plants, Captive Power Plants of Steel

Plants. IL has supplied DDC system

of world- renowned manufacturers to these plants. For small systems PC based

system with single loop controllers has been supplied.

Other

Process Industries: IL

has supplied & executed C&I jobs on turn key basis in Oil Refineries,

Cement, Paper, Fertilizer plants, Nuclear etc. In

addition to Turn-key jobs IL has been doing retails product sale through

Marketing Division and have supplied various type of Instruments to

Industry.Various type of Instruments being supplied by IL are:

- High

performance Microprocessor based SMART Pressure & Differential Pressure

transmitters

- High

performance Microprocessor based SMART Temperature

transmitters

- Microprocessor

based Single & Multi loop Controllers

- Microprocessor

based multi-pen &

multi-point Chart and Chartless

Recorders.

- Microprocessor

based Gas/Liquid Analyzers and

pollution monitoring instruments along with sample handling and conditioning system.

- CMOS

based Integral and Remote type Annunciation

systems

- Flow

elements

- Control

Valves

- Actuators

- Power

Cylinders

- Control

Panels, Desks & racks

- UPS systems